A heat exchanger is an industrial machine transferring one fluid to another fluid without the fluids directly mixing. The exchange between both will transfer the right heat and energy to make the activity works. L’échange de ces deux flux va transférer la chaleur et l’énergie nécessaires à l’activité de l’échangeur. This exchange works thanks to a multiple thin metal plates that are stuck together with small gaps between them. In common language, we can call plate heat exchanger, pasteurizer, sterilizer, evaporator, air-conditioner, refrigerant, etc. And you can find this machine in many industries.

It exists many kinds of heat exchangers as spiral one, blade ones, blocs ones, tubes ones and finally plates ones. Generally, we mostly find tubes and plate heat exchangers on the market.

The heat exchangers don’t receive all the same flux, for this reason they have some specificities of forms.

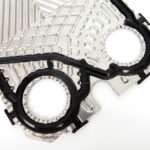

In a plate heat exchanger, the flux alternately moves on each plate. This chevron plates get the flux run on them. The plates are stuck together thanks to several technics: gasketed plates, brazed or welded ones.

The brazed or welded plate heat exchanger are massive and resist to the high pressure (to 30 bar). The gasketed plate heat exchanger is known for their easiest way to clean it and for their facility of evolving. Les échangeurs thermiques à plaques jointées sont reconnus pour leur facilité de nettoyage et d’évolution. Indeed, it is easy to add plates to a gasketed plate heat exchanger thank to the facility to open and close the heat exchanger without influence the gaskets, the plates of the heat exchanger itself.

In this type of heat exchanger, to avoid any risk that both products mixed together, we specially must pay attention to the watertightness between each plate. The plates will be the necessary source of heat for the fluids. These plates are generally made with inox, titan, copper, aluminum and steel.

One of the most critical components of the PHE gasket is its ability to maintain a seal under high pressure and temperature conditions. The gasket must also be resistant to the fluids being transferred, as well as any potential contaminants that may be present. It is essential that the gasket maintains its integrity over an extended period to ensure the longevity of the heat exchanger and to avoid costly maintenance and downtime.

In the case of gasketed plates, we have to pay attention to the high quality of these gaskets to make sure of the watertightness of those. To notice, there are two kinds of gaskets: the clipped and the sticked ones. The elastomer (from the rubber family) is the main ingredient to make a gasket.

Thanks to an epoxy glue, the glued gaskets are stuck to the plates. This glue is made with curing agent and resin, and it is an alternative solution to the welding. The glued gaskets are known for its resistance to the high pression and for its lifetime. If you need to open often your heat exchanger, this type of gasket will be perfect to use because they are known to remain in place.

The clipped gaskets don’t need any glue to tie to the plate. Indeed, they have the particularity to have an additional tie (generally with a T form) along the plate to slip perfectly between the extern chevrons of the plate.

The original gaskets are made by original equipment manufacturer (OEM) which means as manufacturer as Alfa Laval, Kelvion, SPX, SONDEX etc. sell original pieces included gaskets for plate heat exchangers. These gaskets will be called « original gaskets » because they will have the OEM brand and the guarantees included.

A customers looking for gaskets to replace worn ones in his heat exchanger can directly buy news ones to the original equipment manufacturer. Nevertheless, all of the original manufacturer of heat exchangers don’t make all of the pieces of the heat exchanger. They often call a supplier to manufacture their gaskets for their equipment or sometimes they just don’t propose you any solution to find pieces.

The equivalent gaskets are pieces which are not from the original equipment manufacturer but answering to the same standards as OEM. Some companies name themselves « specialist » in the manufacture of equivalent gaskets but every equivalent gaskets companies are not at the same value. Indeed, some of them make low quality gaskets instead of other equivalent gaskets companies make equivalent quality gaskets to the OEM even higher than original.

The equivalent gaskets are known to have the same characteristics as original gaskets. Nowadays, the equivalent gaskets market began to grow again because of the strong demands of industrials. It is obvious that gaskets are from the type of pieces to be regularly changed (more or less following the processus and the liquids used) to make sure of the lifetime of the plate heat exchangers and to limit the risk of mix two liquids.

Choosing a good equivalent gaskets manufacturer is important to ensure that you receive high-quality gaskets that meet your specific needs. Here are some factors to consider when choosing a manufacturer:

By considering these factors, you can choose a reliable equivalent gaskets manufacturer that can provide you with high-quality gaskets that meet your specific needs.

PHEwtur propose you a large range of equivalent gaskets to enable effective maintenance of plate heat exchangers. Among this range, you can count :

Accessen, AGC, Alfa Laval, API Schmidt Bretten, Armstrong, Arsopi, Barriquand, Bell&Gossett, Cetetherm, Cipriani, Corblin, Danfoss, DHP, Fiorini, Fischer, Funke, Graham, Hisaka, IDMC, ITT Standard, IWAI, KAPP, Kelvion, Krashin Eng., LHE, Mueller, Nagema, Nanhua, Pasilac, Polaris, Positron, Reheat, Sasakura, Sentry Equip., Silkeborg, Sondex, SPX, SRP, STORK, SWEP, Tetra Pak, Thermaline, Thermowave, Tranter, Vicarb, Viex, Yibao.

Firstly, our equivalent gaskets are made with the highest-quality materials from Europe, ensuring that they are durable and long-lasting. They are designed to withstand extreme temperatures and pressures, and they won’t deteriorate easily. This means that you can rely on them to keep your machinery running smoothly for a longer period of time, saving you time and money on repairs and replacements.

Secondly, our equivalent gaskets are designed to fit perfectly with your machinery. They are created using the same specifications as the original gaskets, so you don’t have to worry about any compatibility issues. This makes the installation process much easier and smoother, allowing you to get back to work quickly and efficiently.

So, if you want a high-quality, reliable, and affordable gasket solution, choose our equivalent gaskets. Contact us !

Our specialist technicians replace defective plates and reattach new plates directly on site.

We offer you the repair of your heat exchangers in our factories, including disassembly, reassembly and transport.

We offer integrity testing of your plate heat exchangers, with maintenance intervention if necessary, directly on site.